Alchemic Technology - Digital Materials Science Company held an online "Microsoft Group Meeting" on November 5, 2020 to introduce the world's latest technology in polyester dyeing field. At the workshop, the famous senior textile engineers from Bangladesh ran the test operation of the machine.

Figure 1: Alchemie smart waterless dyeing technology ensures higher profit (> 50%)

Key speakers in this seminar were Simon Kiew - CEO of Alchemie Technology and Kevin Myers, the organizer of the seminar. Bangladeshi representative led by Engr. Md Monjur Alam - CEO, Index Apparels LTD presides over. (Bangladesh exclusive agent).

In the online session of the Bangladesh Textile University were Professor Dr. Monirul Islam, Professor Dr. Zulhash Uddin and Associate Professor Abbas Uddin Shayak. In addition, there were also the participation of many experts from many other businesses and organizations such as AK M Mohshin Ahmed - Director (Textile Division), Knit Concern Group; Sayeed Munir, COO (Textile Division), Epyllion Corporation; Engr. Shafiqur Rahaman - CEO, Hams Group; Zaki Ahmed, ED, Snowtex Group; Ruhul Ahmed, GM, Urmi Group; Engr. Enamul Haque, ED, Metro Group; AK M Mushfiqur Rahaman, DGM, Epyllion group, Engr. Mr. Mahbub Milton, ED, Masco group, Arshad, CEO, Sreepur Textile BD; Mohsin Ahmed - Managing Director, Saad Musa Group, Saeed Ahmed - Head of Engineering, Saad Musa Group; Manik, Head of Engineering, Beximco Group, Engr. Shamim - CEO, South West Composite Textile Mills Ltd; Engr. Selim Reza, MD of Afnan Textiles Ltd; Boloram Roy - Metro Group Director; Engr Jewel Palawan, GM of Meghna Group attended the online session.

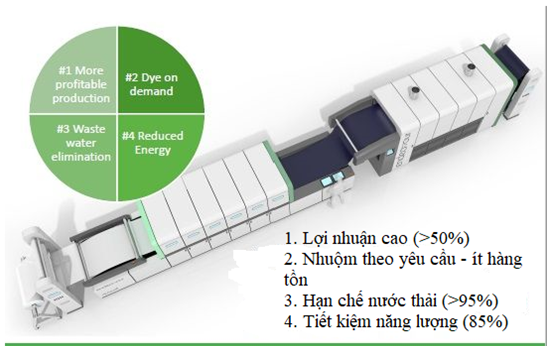

During the keynote speech, Simon Kiew emphasized that Alchemie intelligent waterless dyeing technology guarantees higher returns (> 50%), Dyeing on demand - less inventory and possible waste water removal (> 95%), while helping to reduce energy consumption (~ 85%).

He shared the main benefits of this technology include: making production more profitable, satisfying dyeing on demand, eliminating waste water and reducing energy, as evidenced by some profitable spending. after:

High profit (> 50%)

Simon Kiew, during his speech to the guests, shared the whole process of dyeing polyester without water using Alchemic technology. He also introduces the functions of the different parts of the machine and gives instructions on how to use them.

The technology, he added, is economically viable thanks to its rapid automatic color change and extremely low minimum order counts.

Figure 3: The main benefits of this technology.

Simon ensures that production lines are available for delivery by 2020 with the following functions:

Simon also guarantees excellent color uniformity of this technology, e.g. color uniformity: <0.5 in and between batches.

During the online presentation, many questions were raised from the technology-related guests and were answered in detail by Simon and Kevin Myers.

This type of dye is water-free and low in chemicals, so the question is whether there is a need for special dyes.

In response to the question, Simon said that it was possible to use any brand's available disperse dyes, experiments were performed on this machine in the lab and there was no difference between laboratories. , and can move to mass production. That means 100% of the RFT can be performed by this machine.

One of the most interesting questions raised concerns return on investment (ROI). Simon guarantees that if it is a 10,000,00kg project, the returns will be in 12-18 months.

PUMA, ADIDAS, NIKEE and H&M have their technology and machinery registered to suppliers. Thanks to using this machine, these carriers don't need ETP and it will run on electricity.

The guest requested to hold a practical demonstration of this technology as it is a new technology from Bangladesh. This will make it easier for them to make a product decision.

In general, the seminar took place highly interactive. If this technology can be applied in the Bangladeshi textile industry, it will ensure a more sustainable textile business that does not cause more pollution to the whole industry.

https://vinatex.com.vn/ra-mat-cong-nghe-alchemie-mot-no-luc-moi-trong-linh-vuc-nhuom-khong-nuoc-thong-minh/

Source: vinatex.com.vn