Main trend

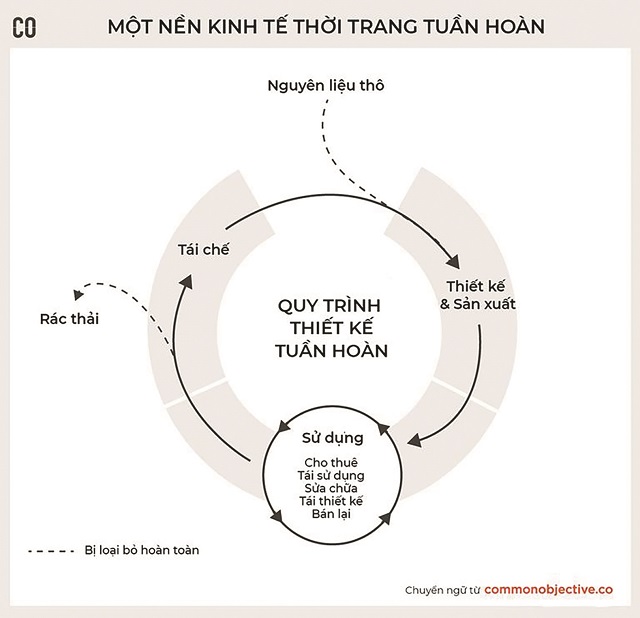

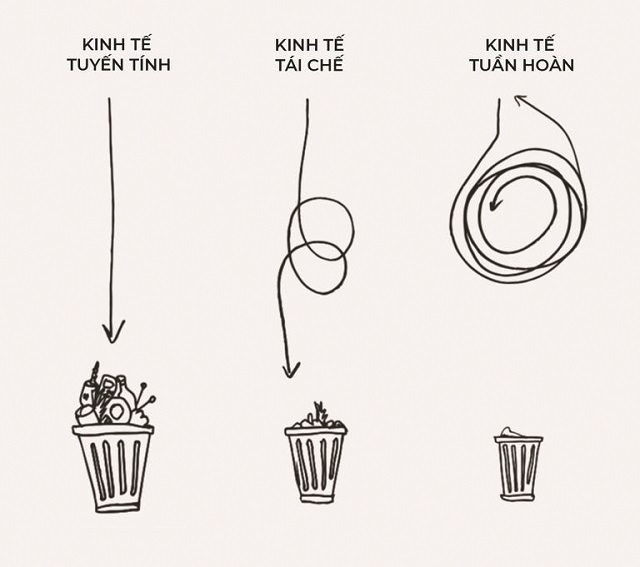

The circular economy reduces the need for new raw materials while keeping the existing materials we are in circulation for as long as possible, with the lowest impact routes available to us. While there are many sustainability aspects to consider, the concept of a circular economy really focuses on the environmental impact of raw materials. It is an important part of the trend that fashion brands are planning to reduce their carbon footprint in the long run – but not the only part.

With this in mind, we decided to give an overview of the main priorities in order of importance for creating a true circular economy in the fashion industry. These priorities bring us back to the classic 3R concept of “Reduce, Reuse and Recycle” decades ago and the many modern variations of the concept. These concepts still hold true today, we need to make full use of energy usage trends at least first, before moving on to more energy-intensive and incremental solutions.

Five priorities of the circular economy in the fashion industry

Reuse and repair

It is often misunderstood that recycling is the only key way in creating a circular economy in the fashion industry. One of the best ways to reduce the need for raw materials is to reuse and repair the garments that are in circulation. The reason is that the production of textiles, then garments, uses energy, and in most cases is still powered by fossil fuels. For consumers this means buying used goods whenever possible and repairing garments when they show holes; For brands, this means investing in their own repair programs, resale platforms and return services, while designing garments that last longer and repairable.

Remake

Garments can also be structurally demolished and remade into new items with new styles, fit, and sizes. This is essentially “recycling” the fabric that has been made into a garment, transforming it into something new without further destroying the structure down to the fiber. Designing easy-to-remove garments is a strategy to aid in easier structural destruction and easier re-sewing into other garments. This can also be an important intervention for pre-consumer or post-industrial waste such as unsold inventory, overproduction or consumer returns, which may not be damaged but may not be resold in any way.

Recycling

Even when textiles have been used to their maximum possible life, through continued reuse, repair and the potential to be remanufactured into new garments, the garment will even reach the end of its life. useful. Garments may be too lint, rotten or soiled to no longer be used for any other purpose. At this point, recycling is often the best way available.

For the best-case scenario for a circular economy in the fashion industry, textile recycling should result in a product (i.e. fiber or yarn) that can be substituted for the original “brand new” material on the market. market, with a process with a lower carbon footprint than that of producing raw materials. If so, closed loop fiber recycling would reduce carbon emissions and other impacts by reducing the separation and processing of virgin raw materials. This concept is often referred to as “fiber to fiber” recycling, and has received a lot of attention in recent years. However, there is still a long way to go before it is a reliable choice for most “end of life” textiles. There are many technical, economic and social barriers to scaling up fiber-to-fiber recycling technology that require huge investments, legislation and economic incentives to overcome.

The fact that the garment itself is made from recycled materials does not mean that it is automatically recyclable. For example, most recycled polyester is made from PET bottles for drinking water, not textiles. As the garment reaches the end of its life cycle, there are very few facilities that can recycle it, and so the process is currently "straight" (i.e., not cyclical).

It should always be remembered that designing garments to be recycled, for example by using only one material, avoiding certain additives, dyes and pigments etc. However, most designs for garment recycling are for end-of-life scenarios that do not currently exist in most cases, and the possibility of recycling is theoretical. In addition, a wide range of technologies for textile recycling are under development and the impurities that can interfere with recycling processes vary over a wide range. There is no uniform standard that makes textiles “recyclable”. As more recycling options will be available in the future, designing for recycling will naturally become important in ensuring high efficiency in the recycling system.

Composting and decomposition

Depending on the material, the pursuit of composting garments as a trend towards the end of the primary life may or may not be beneficial at all. From a recycling economy point of view, although carbon can be considered to be 'recycled' by incorporation into the biosphere, the material or polymer itself is destroyed and the new raw material is purified. produced to “fill the gap” in production.

If enough energy is available to produce these new materials (as with many other biopolymers) then composting will lead to a net increase in carbon emissions when compared to recycling. However, there are also potential cases where the impact of the natural fiber material could be lower than the potential recycling process. In this case, considering composting may be appropriate, although second-hand textiles can also be used as feedstock for the production of other fibers such as rayon. In this case, it is necessary to consider which scenario reduces the global greenhouse gas emissions as a 'system'. It is therefore possible to consider composting in locations where recycling is not accessible and where other value-creating pathways are not currently available. However, there are also many considerations in terms of garments that can be composted. This needs to be accounted for in the design of this commodity and its end-of-life handling.

Take advantage of the useful value of raw materials

After most of these options have been exhausted, the best remaining option is to extract the small useful value remaining from the materials after they have reached the end of their life. In some cases, it is possible to burn textiles to produce energy for the grid. Recycling of mixed waste by pyrolysis and gasification is also advocated to convert mixed waste (including textiles) into small molecular hydrocarbons. However, in most cases on the fashion side it is not a recirculating system, as most of the output will be products that are burned as fuel and most of the materials used in the fashion. cannot be "re-synthesized" from the molecules in the output. Although several molecules can be used to synthesize polymers, this is now mostly directed towards plastics for packaging or used in fashion materials in small amounts such as cellulose acetate.

Hoang Thu Ha (translation)

https://vinatex.com.vn/nhan-dien-nen-kinh-te-tuan-hoan-trong-nganh-thoi-trang/

vinatex