SmartX has just sent out a final call to promote activities of application projects, companies can register until February 15 to ensure funding up to £ 60,000 for each application.

Melanie Hoerr, of ZSK, based in Krefeld, explains that to create smart fabrics, three of the company's separate embroidery heads can be combined in a single machine.

At SmartX's latest online meeting, the European Smart Textile Promotion Project, which took place on October 9, flat knitting flexibility and embroidery productivity in the creative and commercial sectors. New smart fabrics commercialization was emphasized.

SmartX has just sent out a final call to promote activities of application projects, companies can register until February 15 to ensure funding up to £ 60,000 for each enterprise.

Following the success of the second call, in June 2020, the project has received high attention from the textile and technology industries, despite the ongoing Covid-19 pandemic. As a result, as many as 29 enterprises completed application deployments, 19 of which were submitted by the association. A total of 56 SMEs from 16 EU and other affiliated countries are registered. Most of the proposals mention the healthcare market, while the remainder focuses on health care and protection.

Backed by the European Union's Horizon 2020 research and innovation program, the 3-year SmartX Europe program is supporting up to 40 smart textile projects with a total budget of 2.4 million euros and also provides one-year free training to help startups and small-scale businesses grow their technology and establish the contacts they need.

“Having selected 20 projects worth more than 1.5 million euros in the first two SmartX calls, we are currently looking for the third and final group of pioneering projects ready to conquer the niche markets. attractive in the fields of protection, sports, health and industrial markets with innovative smart solutions in the textile industry ”. Lutz Walter - Secretary General of ETP Textile, a SmartX partner and program coordinator said. The project development base is driven by a joint venture of 13 European partners from the textile and technology industries.

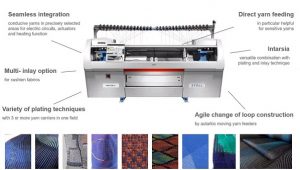

Stoll ADF

According to Alexander Behm, Stoll's Technical Textile Product Manager, the company's ADF flat knitting machine can be used to create a myriad of new smart fabric designs, through intarsia weaving techniques, plated and layered to integrate specific functionality of silver-coated polyamide or stainless steel or pure copper fiber to create flexible conductors for heating elements, sensors and actuators.

© Stoll.

Many deals have been made through Stoll's partnership with Myant, which includes other notable deals, including heated garments marketed by Germany's WarmX.

A current medical application also made by the Stoll system is the use of a mesh knitted gold thread that is used as an electrode in the device to transmit radio frequency (RF) energy in the treatment of dysmenorrhea.

However, perhaps the most complex product created so far on the Stoll system is the glove made for Robert Bosch - Europe's largest supplier of auto components, with 2019 sales of 77 7 billion euros.

Stoll's seamless knitted gloves were made for Robert Bosch - Europe's largest supplier of auto components.

© Stoll.

This seamless 3D flat knitted glove is made of sensor fiber allowing the wearer to perceive and control applications during human-machine interaction.

The intarsia weaving technique has been used to create the conductive and flexible sensors of gloves at the tip of each finger, and the selective plating technique allows 12 electrical paths, each based on a single fiber feeder. , is positioned precisely.

"The sensors are integrated in a tubular construction and we use elastic fibers to give comfort to the custom glove shape," says Behm. "The gloves still retain their breathable functionality, despite the intricate design."

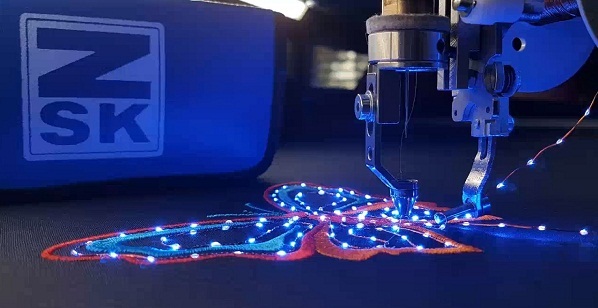

ZSK multi-head embroidery machine

According to Melanie Hoerr, ZSK's embroidery technical director, based in Krefeld, Germany, to create smart fabrics, three of the company's separate embroidery heads can be combined in a single machine. :

The F-head, most commonly used for decorative embroidery and has been used to mass produce fiber-based smart fabrics containing LEDs and RFID chips linked to PCB (printed circuit boards), is the first part that is fixed to the fabric base, followed by the electrical paths embroidered from it to the individual sensing areas.

- K-head for realizing 3D shape-matching patterns built in loops on the base fabric - also known as 'embroidery' - to create very good conductive areas for reading biological signals. via 'dry' sensor. The embroidery sensor provides closer contact with the body in the measurement of vital signs for clearer and more effective signals. "This makes it possible to feel the sensor without seeing it," says Hoerr.

K-head, for tailor-made wire positions such as heater, electroluminescent, RFID transceiver in any shape. A video shows these 11 ends connected in series like a heater that fills the seat cushions of a car at 2,000 / 24 hours of operation.

ElectroSkin electrode membrane

Smart textile consulting firm Titeria member Daniela Zavec gives a better look at how the Swiss company Nanoleq, where she has worked, is making smart fabrics for biosensors and applications. Other applications are accessible for newcomers to the field.

Nanoleq has developed key components that can be easily applied to textiles through hot rolling.

Nanoleq has developed key components that can be easily applied to textiles through hot rolling.

"Crucially, Nanoleq has developed not only the film electrode components but also a complete test protocol for washability, extended resiliency, and chemical resistance," Zavec said. and other performance attributes, to ensure the quality of the new products based on these components ”.

According to Nanoleq, their ElectroSkin electrode films are light, thin, and their skin impedance is even better than standard medical gel electrodes, without wetting and even after repeated washing.

A starter kit consisting of 12 ElectroSkin electrode films, insulation stickers for connections, conductive shutter buttons and support tools for laminating and pressing, a layered reference pattern and SOP documentation are available from The company costs £ 880, which includes 90 minutes of telephone support on lamination and connection issues.

Could creating new smart fabrics be easier?

The final call for project SmartX applications will open until February 15.

https://vinatex.com.vn/det-phang-theu-va-do-tu-che-cac-cong-cu-smartx-thong-minh-cho-tuong-lai/

Source: vinatex.com.vn