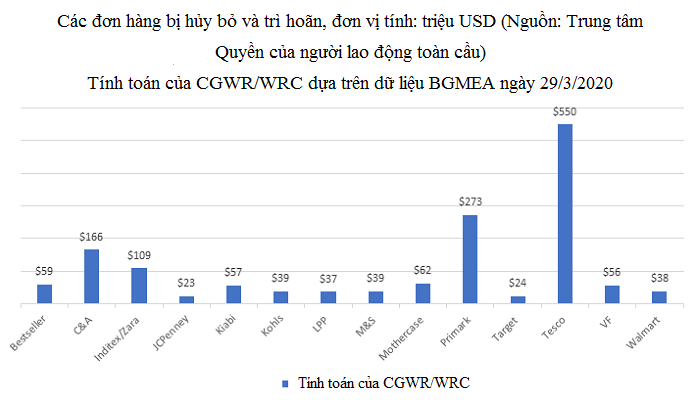

The chart below is a new report that lists fashion brands that have canceled or delayed most of their orders from suppliers in Bangladesh, where more than a million garment workers have lost their jobs due to the COVID- 19.

Primark canceled or postponed most orders, for a total of $ 273 million, followed by C&A ($ 166 million) and Inditex / Zara ($ 109 million), according to the report. report of the Center for Global Workers' Rights, of the State University of Pennsylvania.

Mothercare ($ 62 million of orders canceled or delayed), Bestseller ($ 59 million), Kiabi ($ 57 million), VF Corp ($ 56 million), Tesco ($ 50 million), M&S ($ 39 million), Kohls (US $ 39 million), Walmart (US $ 38 million), LPP (US $ 37 million), Target (US $ 24 million) and JC Penney (US $ 23 million) were also included.

Fashion giants H&M and PVH with a large volume of outsourced goods from the Bangladesh market are not included because they have agreed to pay factories for orders that have been canceled.

The statistics include orders processed, with a total value of $ 1.45 billion, and orders expected by the end of this year, worth $ 1.69 billion. , for a total of 3.14 billion US dollars.

“Shops in every country where we operate are closed. As a result, we are losing £ 650 million in sales per month. Therefore, we have no other choice, ”a Primark spokesperson said

“Right now we have a large amount of paid stock in stores, storage and in transit. If we do not take this action, we will have to take stock quantities that cannot be sold. This is an action that was unprecedented in the past and unimaginable ”.

“We at Primark have worked with many suppliers for many years and the value of our relationships is enormous. We are aware and sad that this will affect our entire supply chain.

“We communicate closely and frequently with our suppliers and very much hope that regular trading relationships can recover as soon as possible. In addition, we strongly urge governments in the countries to supply our products, taking action to support local businesses and workers like the UK and many European governments do. . "

“We will do our best to follow our promises and receive products that are already in production. We are aware of our responsibility and are in close dialogue with each of our suppliers about how to handle the current crisis ”. Bestseller Chief Financial Officer Thomas Børglum pledges

“We have to overcome this situation by working with suppliers. "We want to assist our suppliers with ordering for the next seasons."

The Global Workers' Rights Center said it calculated the figures based on data from the Garment Manufacturers and Exporters Association of Bangladesh (BGMEA) - although BGMEA declined to provide information. researchers.

Reported under the headline “Abandoned? The Impact of COVID-19 on Workers and Business at the Bottom of the Global Garment Supply Chain ”written by center director Mark Anner, affiliated with the Workers Rights Association.

"The global COVID-19 pandemic has had a devastating impact on global apparel supply chains, and the situation will get worse before the epidemic is stopped," he wrote.

“Clothing stores were closed because of the shutdowns of developed market economies, demand for garments fell, brands and retailers were quickly canceling or postponing orders. manufactured goods, in many cases refusing to pay for clothes that the supplier's factories have produced ”.

"The result is the partial or complete shutdown of thousands of factories in the producing countries, leading to millions of factory workers being laid off at home, often unpaid or legally laid off" .

The report carried out an online survey of 316 plant owners in Bangladesh. The authors say that a number of such sites out of 2000 plant owners in Bangladesh can guarantee up to 95% confidence in the results.

According to the report, 45.8% of respondents said that 'a lot' to 'most' of their almost completed or completed orders were canceled by the buyer and 5.9% canceled all of these orders.

Buyers have contractual obligations to pay for these orders, the report said, but they used general force majeure clauses to justify breaches of the terms of the contract.

The survey found that 72.1% of buyers refused to pay for purchased raw materials to fulfill their order and 91.3% refused to pay production costs.

And 98.1% of buyers refused to contribute to the reduced wages paid to laid-off workers, for which they were legally entitled and 97.3% refused to contribute to pay severance pay.

Due to cancellations and lack of payments, 58% of surveyed factories shut down most or all of their operations. Nearly all were then closed in Bangladesh because of the government shutdown.

The report concludes that brands and retailers should seek access to credit or government support to cover their obligations to supplier factories to avoid millions of workers being laid off. We don't have money to buy food, let alone medical expenses.

“First of all, there is a need to rethink how the industry works. Purchasing operations must be reformed for environmental and social sustainability ”, which should continue to be addressed.

https://vinatex.com.vn/covid-19-tac-dong-tan-pha-doi-voi-chuoi-cung-ung-hang-may-mac-toan-cau/

Source: vinatex.com.vn