Man-made fibers (MMF) are considered the future of Bangladesh's apparel industry because the demand for this product is growing strongly around the world as more intelligent consumers increasingly try to make the world greener. by reducing consumption of items that are harmful to nature.

FIGURE 1: Artificial fibers - the future of Bangladesh's textile and apparel industry due to increasing consumer demand worldwide.

Create a greener world

A green and sustainable world is the goal of mankind. That does not mean focusing solely on building green factories to save on lighting costs, energy and reduce water consumption.

On a larger scale, green development means turning waste, especially plastic products into other products by recycling for the world environment, especially the ocean environment and aquatic resources. The natural ecology is threatened by plastic products because it takes several hundred years to decompose. Therefore, recycling waste into other products is also an action that contributes to making the world greener. Reducing consumption of products harmful to nature is also a major part of this campaign. Bangladesh will have to gain more market share in the global apparel industry for the sustainability of the domestic textile industry. Domestic garment manufacturers will also have to use man-made fibers, although the current pace is still slow.

Real investment

Bangladesh's product size is small compared to China or Vietnam because it is still limited to cotton products. Therefore, Bangladesh has the opportunity to diversify its products by using man-made fibers - an undiscovered material in Bangladesh. Mr. Matin Chowdhury - CEO of Malek Spin Mill, a leading yarn company. Textile said setting up the MMF artificial yarn factory is very expensive.

Mr. Matin Chowdhury also added, “I tried to set up an artificial fiber factory for 10 years before the project cost was estimated at 100 million dollars and now it takes from 400 million to 500 million. dollars. Therefore, very few investors are interested in this costly production trend. ”

However, he also agrees that the demand for man-made garments is on the rise worldwide and that the Bangladeshi textile mills will also have to set up mills operating in this direction. "If not, the country's $ 8 billion key textile and apparel industry will soon be in big trouble," he added .Seded M. Tanvir, Director of Pacific Jeans Ltd, said: "Like cotton, man-made fibers." Do not fluctuate with gasoline prices. Because we do not produce cotton, but we rely heavily on cotton, we can expand our market by starting to produce artificial fibers instead. When it comes to manufacturing technology, this is not a problem because technology is a commercial product. So if we can produce the right products, technology and materials, that's not the point. “We have to recognize the problem that we are having difficulty with the source of cotton. So why not switch to artificial fibers? In this regard, I think that inexperienced Bangladeshi textile mills are ambiguous when approaching the production of man-made fibers. There is a need for someone who is pioneering so others will follow, ”Mr. MMvirvir emphasized

The good signal is that some leading companies have gone in this direction such as DBL Group, Habitus Fashion Ltd, Fakir Apparels Ltd, Debonair Group, etc.

The Debonair Group is about to set up a recycling facility to recycle plastic waste into fibers, which will be used to produce jackets and blankets to meet the global demand for man-made fibers and increasing awareness. increase in the environment.

Mohammed Ayub Khan, CEO of Debonair Group, said the new facility would be established on 45 plots in Bhaluka at a cost of Tk 240 million and production will begin in October this year.

The company will no longer depend on imported raw materials with a total import value of about 55 million dollars annually and mainly from China.

“We will collect plastic bottles from across the country and then shred and spin the thread, then weave it into fabric and eventually produce mattresses and blankets.” The Debonair Group is currently exporting jackets and mattresses with a turnover of 140 million dollars a year. According to a new report published in the Daily Star, the company's main customers are H&M, Colombia, VF Corporation, Benetton Group.

Figure 2: The Debonair Group currently exports jackets and mattresses with a turnover of $ 140 million a year

Import of man-made fibers is increasing

With the rise of the high-end smart fashion market worldwide, the demand for man-made fibers is also increasing. Due to lifestyle changes, consumers are looking for easy-to-use products. Therefore, the import of man-made fibers such as polyester, viscose and Tencel fibers is increasing in Bangladesh.

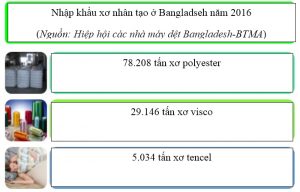

Tencel imports, a type of fiber made from stems and leaves, were 5,034 tons in 2016 and last year were 6,199 tons. Monsoor Ahmed, secretary of BTMA, said that the import of man-made fibers is increasing every year. According to the textiles, the durability and longevity of man-made fibers are higher than those made from cotton. That is why the demand for man-made fibers is increasing. If clothes made of man-made fibers are not washed for several days, their quality will not deteriorate or excessive washing will not degrade quality. Bangladesh imported 78,208 tons of polyester fiber in 2016, an increase of 11.39% compared to 70,209 tons in 2015 and an increase of 35.72% compared to 51,729 tons in 2014, according to data from the Bangladesh Textile Mill Association (BTMA). ) Import of viscose yarn was recorded at 29,146 tons in 2016, down slightly from 29,538 tons in 2015. From January to June 2017, the import volume was 16,063 tons. In 2014, Bangladesh imported 18,115 tons of viscose fiber.

Production of man-made fibers is also growing.

The number of factories producing artificial fibers also increased. Only polyester yarn factories, compared with 7 years ago, the number of factories increased to 52 from 10 to 12 original factories. There are 45 viscose fiber mills and 10 Tencel yarn mills. Globally, the proportion of man-made fibers has increased compared to cotton, although cotton is still a staple of spinning machines. The ratio of fibers made from cotton and man-made fibers has increased to nearly 80:20, even compared to five years ago at 90:10.

According to a recent study by the Bangladesh Association of Garment Manufacturers and Exporters (BGMEA), garment exports of domestic manufacturers have remained at 20% for many years despite the market. In the world market, the production of man-made fibers has exceeded 40%.

While the worldwide production and consumption of man-made garments is increasing, cotton and Bangladeshi cotton products are also increasing every year. Therefore, domestic exporters can only sell cotton garments at low prices to buyers.

Cotton yarn still dominates the Bangladesh marketThe study also said that, in total apparel exports from Bangladesh in the 2018-2019 fiscal year, exports of cotton products accounted for 74.14% and Bangladesh's share in this segment was 68.67%. In the 2008-2009 fiscal year, not only focused on cotton yarn, Bangladesh's exports also focused too much on five garments, such as t-shirts, pants, vests, sweaters and shirts. And these top five exports accounted for 73% of total apparel exports for the past fiscal year, specifically, BGMEA research says Bangladesh exported $ 7.01 billion worth of T-shirts. , $ 6.93 billion pants, a $ 4.38 billion jacket, a $ 4.25 billion sweater and a $ 2.32 billion shirt. Mr. Ziaur Rahman, Area H&M Director Bangladesh, Pakistan and Ethiopia said the trend of garment exports from Bangladesh had a greater focus on cotton apparel, while global consumption was shifting to man-made fibers. The president of the BGMEA association also agreed with the trend of manufacturing garments from artificial fibers. However, Bangladesh needs foreign direct investment and government support in order to produce garments made from man-made fibers.

The government should also loosen regulations to attract foreign direct investment in textile production from man-made fibers because Bangladesh's production capacity in this direction is currently very low, Huq said in a discussion. recently. The BGMEA study also showed that out of 20.52,000 tons of fiber imported to Bangladesh in 2018, cotton accounted for 93.57%.

The proportion of garments made from man-made fibers is about 45% of the global trade value, up 5% of the annual growth rate (CAGR) in the same period. In 2017, global trade in man-made garments was $ 150 billion, of which Bangladesh accounted for 5% while Vietnam was 10%. On the other hand, the global trade share of cotton apparel is about 35%, and is shrinking at 0.5% of CAGR's annual growth rate between 2007 and 2017. .

Source: vinatex.com.vn